Process Water

Water is used in Pharma for production, process, for formulations, for CIP and in Quality control process. Water is required on demand in Pharma processes.

Ozone is used in Process Water treatment mainly as insurance of quality. Ozone is eco friendly and does not leave behind any residues is very small which also prevents proliferation of pathogens .Ozone does not Produce any DBP or toxic compounds.

However Proper Implementation, Automation, Measurement, Validation, injection and Destruction of Off gases along with IQ,DQ OP standards should be maintained for Process water Application.

CIP ( Cleaning In Place):

The use of ozone sanitizing in CIP (Clean in Place) systems offers many advantages across several industries. Ozone is an environmentally friendly disinfectant that leaves no residual, or by-products. Ozone is a safe sanitizer with no need for chemical storage, or handling, thus eliminating the related safety issues.

Applications Features

- Ozone has no residuals or by-products that could alter flavors of a beverage or other product.

- Ozone sanitation may replace hot water cycles, lowering energy costs.

- No Harmful Chemicals like chlorine or other sanitizers can be eliminated.

- CIP rinse/cleaning cycles can be combined using ozone; saving water and time.

- More processing time, due to a shorter CIP cycle time.

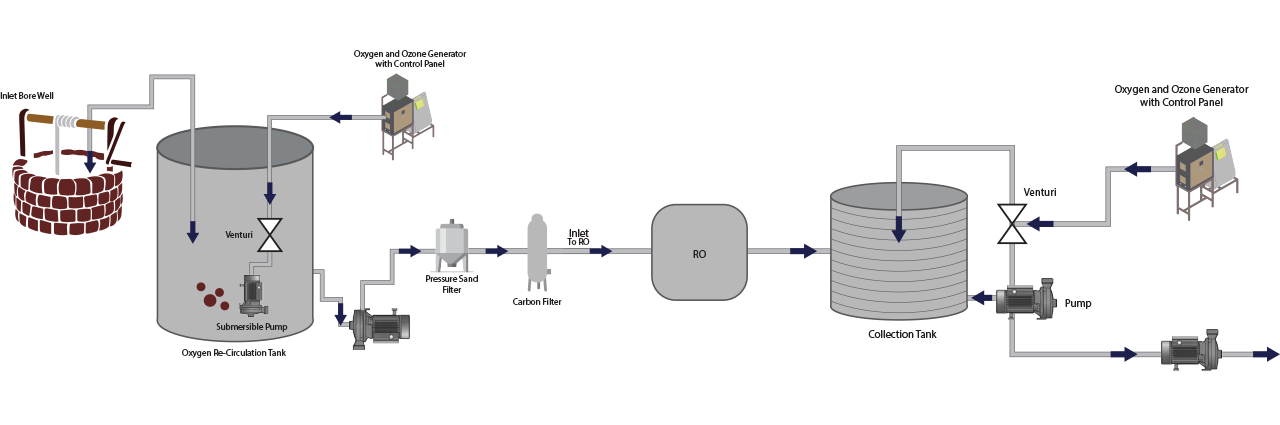

*Diagrams are subject to changes as per design and applications